ABOUT US

Home » About us

About YIERYING

Fujian Nanping Yierying Garment Co., Ltd. is headquartered in Yanping District, Nanping City, a famous textile base in East China. It was established on January 18, 2011. It focuses on the design, development, production and manufacturing of high-quality knitted garments, creating a supply chain operation model, improving industrial layout, sharing resources and complementary advantages, and improving corporate innovation and comprehensive competitiveness.

We are a rapidly developing, integrated clothing company that integrates design, production, and sales through OEM and ODM brands.

Business philosophy

Intelligent Manufacturing System Architecture

Equipment Layer:

Introduces industrial robots, machine vision inspection systems (99.9% defect recognition rate), and IoT sensors to monitor the status of production equipment in real time;

Control Layer

Integrates an intelligent hanging system through the OPC UA protocol, enabling linkage between piece-rate payment via barcode scanning and a large-screen visualization of production data;

Information Layer

Deeply integrates ERP and MES, connecting order management, process execution, and quality traceability throughout the entire process, increasing the yield rate to 98.5%.

Flexible manufacturing and customization capabilities

Modular Production Line Design

Utilizing SOA architecture for rapid production line reconfiguration, and employing U-shaped layout and digital twin technology, it supports parallel production of multiple styles, improving efficiency by 40%.

C2M Platform Empowerment

A smart customization system is built, supporting online material selection and functional customization (temperature control/antibacterial). The APS scheduling system enables 72-hour delivery, with customized business accounting for 25%. AI algorithms aggregate scattered orders and match them with worker strengths.

Data-driven and supply chain collaboration

Industrial Big Data Platform

Collects 2 million data points daily, including equipment energy consumption and process parameters; machine learning algorithms enable predictive maintenance, reducing downtime by 65%.

Vertical Ecosystem Integration

Self-developed OEM/ODM collaboration platform connects 2000+ supply chain companies, promoting real-time sharing of design, manufacturing, and logistics resources, shortening R&D cycles by 30%.

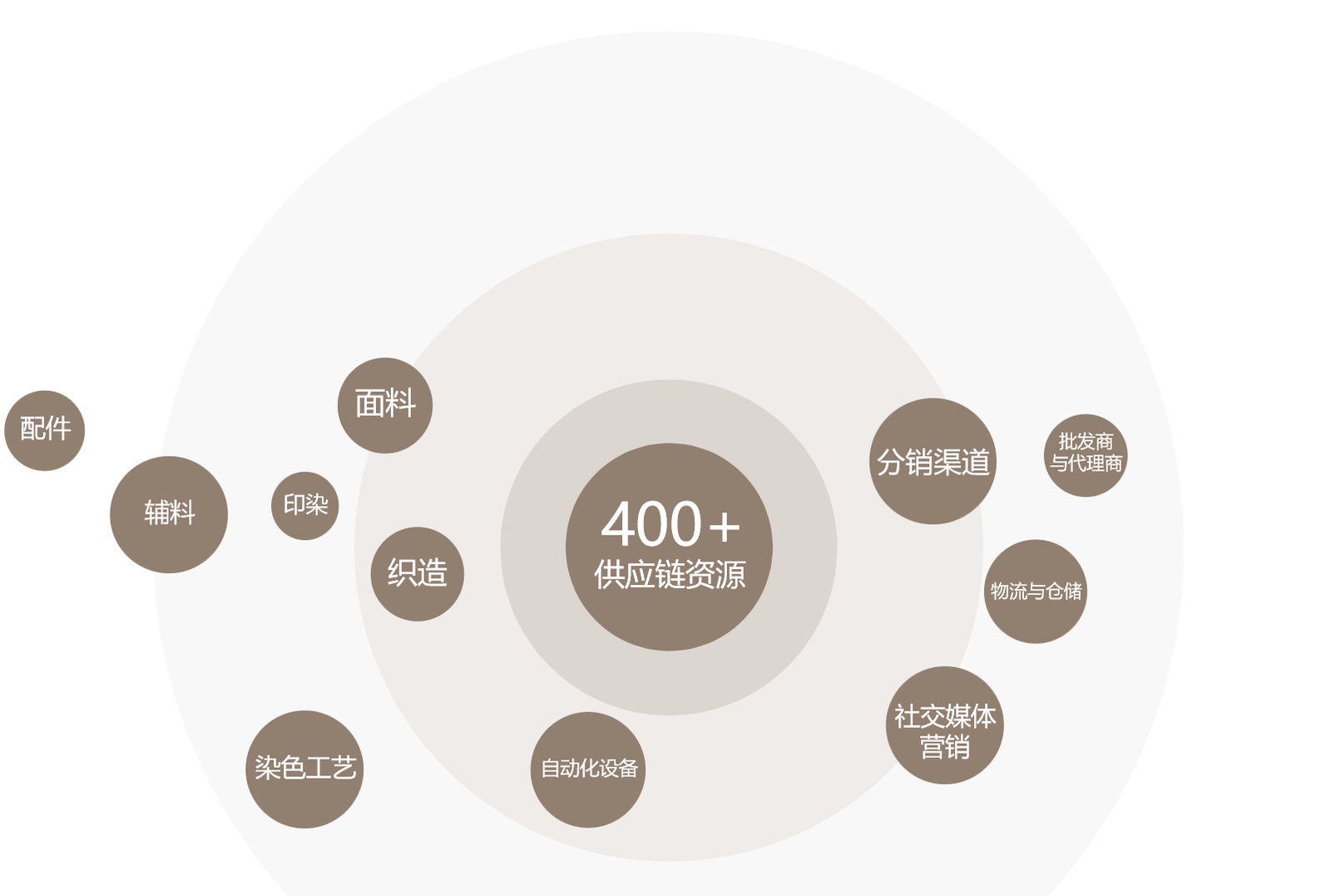

Supply chain management capacity

Market Prospect

Yirui is reshaping the value distribution rules of the apparel supply chain through a strategic layout of digital R&D, flexible production capacity, and intelligent services, providing the industry with a small-batch, rapid-response upgrade paradigm characterized by “low-risk trial and error + highly agile delivery + strong compliance assurance.”

Yirui’s intelligent upgrade is a strategic fulcrum for breaking through homogeneous competition in the industry and seizing the high-end incremental market. Through the digital flexibility built on “system integration + intelligent production lines,” it can form a moat in three aspects: achieving small-batch, rapid-response efficiency (delivery time reduced to 20 days), ensuring high-end quality control (defect rate <1.5%), and supporting intelligent customization (72-hour delivery).

Prioritizing the implementation of ERP (order/financial modules) and intelligent production lines, and simultaneously connecting with high-end brand OEM orders for knitted fabrics, it achieves a 30% return on technology investment. In the long term, it will output production capacity through a “shared intelligent manufacturing platform” model, upgrading from a manufacturer to an apparel technology solutions provider, opening up a market space worth billions.

系统名称 | 核心功能模块 | 预期效益提升 |

自研ERP软件 | 小单成本核算、ESG认证对接 | 小单毛利率+3-5%、合规认证效率+70% |

MES系统 | 工序实时监控、混流生产调度 | 次品率降至1.5%、换款时间缩短85% |

智能WMS | RFID追溯、自动配料 | 停工减少30%、追溯效率提升90% |

MRP系统 | 区域化需求预测、智能调拨 | 库存周转加快33%、滞销品减少67% |